Mould Craft Tech

Elevate your Precast Factories

We are the driving force behind modern construction, leading the charge in factory automation, custom equipment, factory design, project management, and GFRC solutions. We empower your projects with unmatched speed, scalability, and sustainability.

From initial concept to seamless commissioning, our unmatched expertise in turnkey precast setups and high-performance machinery is engineered to help you build smarter, faster, and stronger

About Mould Craft Tech

Mould Craft Tech is a global consultancy and manufacturing powerhouse, transforming how precast construction is designed, executed, and scaled. We deliver tailored technology and turnkey solutions that drive quality, efficiency, and innovation in precast operations worldwide.

Complete setup of precast & GFRC factories

Bespoke design and fabrication of production machinery

Performance upgrades for existing plants

Supply chain support with compatible accessories and consumables

Our Promise

Engineered Precision. End-to-End Support. Long-Term Value.

Reliability

Trusted by industry leaders worldwide

Engineering

Advanced technical expertise and innovation

Trust

Proven track record of successful projects

Our Solutions

Comprehensive precast & GFRC manufacturing solutions from factory setup to ongoing support. We deliver engineered precision, end-to-end support, and long-term value for your operations.

Factory Setup & Consulting

Complete turnkey solutions for precast & GFRC manufacturing facilities

Greenfield layout design & production line architecture

Intelligent equipment selection & automation planning

Site commissioning, trial runs, and production onboarding

Custom Equipment Fabrication

Bespoke manufacturing equipment designed for your specific requirements

Steel moulds (side shutter, trench mould, box culvert), tilting tables, casting beds, battery moulds, 3D molds, gantry cranes and customize moulds

Tailored to your project needs and manufactured in-house

Shipped worldwide and commissioned on-site by our experts

Process Optimization

Advanced solutions to enhance efficiency and operational performance

Automation upgrades & real-time data monitoring

Higher throughput, better consistency, and lower costs

Accessories & Consumables

Comprehensive supply chain support for ongoing operations

Machinery spares, anchors, lifting hooks, hardware & inserts for precast systems

Recurring consumables with reliable replenishment plans

Our Manufacturing Excellence

Industrial Fabrication

Custom equipment manufacturing

Precast Manufacturing

Complete facility solutions

Precast Panel Assembly

Precision manufacturing systems

Industries We Serve

Our expertise spans across diverse sectors, delivering specialized precast and GFRC solutions tailored to meet the unique requirements of each industry. From residential developments to major infrastructure projects, we provide comprehensive manufacturing capabilities.

Residential & Commercial Precast Plants

Complete precast manufacturing solutions for residential towers, commercial buildings, and mixed-use developments

Infrastructure Projects – Metro, Rail, Bridges & Roads

Heavy-duty precast solutions for transportation infrastructure, including metro systems, railway networks, bridge construction, and highway projects

Mobile Casting Yards for Remote Projects

Portable and modular casting solutions designed for remote locations and temporary project sites with full mobility and efficiency

Modular Housing & Smart Cities

Advanced precast systems for modular housing projects, smart city developments, and sustainable urban construction initiatives

Architectural GFRC Panels & Custom Precast Features

Specialized GFRC manufacturing for architectural facades, decorative elements, and custom precast features with precision finishing

Why Choose Mould Craft Tech?

Selecting the right industrial partner is crucial for project success. At Mould Craft Tech, we offer distinct advantages that set us apart in the industry and ensure exceptional outcomes for our clients. Beyond these core strengths, we also pride ourselves on efficient delivery with a proven track record of completing projects on schedule and within budget. Our comprehensive support system provides continuous after-sales service and dedicated customer assistance throughout the lifecycle of your equipment and facilities.

Expertise & Experience

Our team brings years of hands-on experience across diverse industries. We apply proven solutions with knowledge of industry trends and advancements.

End-to-End Solutions

We serve as a single point of contact for entire project execution — from planning through commissioning.

Quality Assurance

Our work follows strict quality standards and documentation at every stage.

Efficient Delivery

Proven track record of completing projects on schedule and within budget with minimal disruption.

Comprehensive Support

Continuous after-sales service and dedicated customer assistance throughout the lifecycle.

Certified Excellence

Featured Projects: Heavy Machinery Installation

This project involved the delivery, positioning, and installation of large-scale industrial machines. We solved critical challenges, including transportation through urban areas and system integration within a tight facility — executed with high precision and speed.

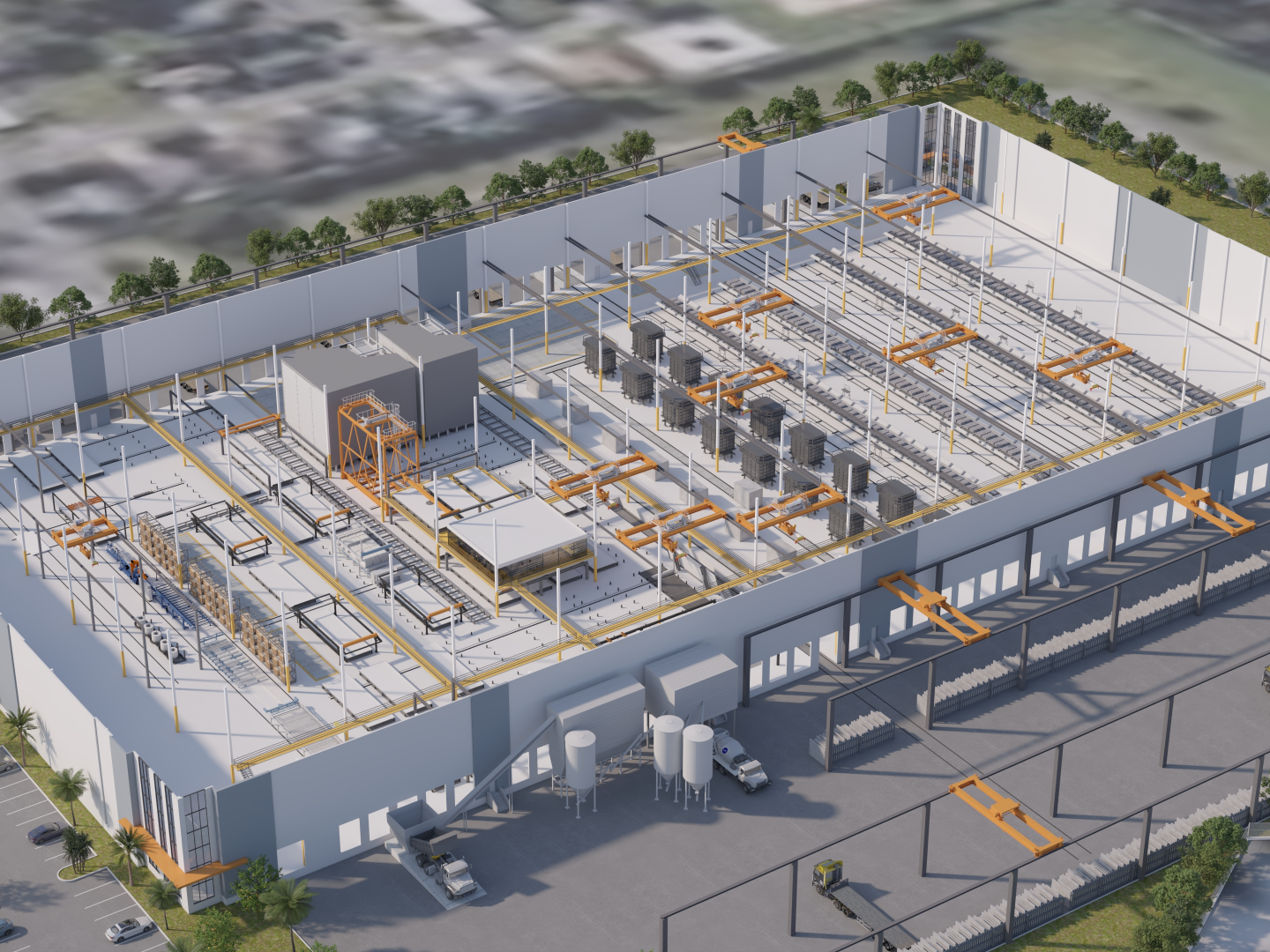

Advanced Manufacturing Facility Setup

Precast production facility with yellow overhead cranes and blue automation systems

Project Milestones

Project Planning

Developed a detailed installation plan and lifting sequence, working with local authorities for permits.

Equipment Transportation

Managed specialized transport of machinery up to 25 tons, using escorts and traffic control.

Precision Installation

Used laser alignment and vibration isolation for precise anchoring and noise mitigation.

System Integration

Connected machines to power, pneumatics, and control systems. Performed calibration and testing.

Featured Projects: Custom Metal Fabrication Plant

We designed and built a complete metal fabrication facility. The project included custom tooling, optimized workflow, and significant cost/efficiency improvements.

Complete Facility Transformation

Custom tooling and optimized workflow design

Cost Reduction

Reduced per-unit cost by process optimization

Capacity Increase

Improved layout and workstation planning

Setup Time Reduction

Custom jigs and fixtures for faster changeovers

Our Comprehensive Project Approach

Our proven 6-phase methodology ensures consistent project quality from initial consultation to ongoing support, minimizing risk and optimizing outcomes for every industrial solution we deliver.

Initial Consultation & Requirements Analysis

We begin every project with a comprehensive consultation to understand your specific needs, challenges, and objectives.

Detailed Design & Planning

Our engineering team creates comprehensive designs and detailed project plans based on your requirements.

Implementation & Construction

Skilled technicians execute the project with precision, following our quality standards and safety protocols.

Testing & Commissioning

Comprehensive testing ensures all systems meet specifications and operate safely and efficiently.

Training & Handover

We provide comprehensive training to your team and ensure smooth transition to operational status.

Ongoing Support & Maintenance

Our commitment continues with ongoing support, maintenance services, and system optimization.

Why Our Process Works

Our systematic 6-phase approach ensures consistent quality, reduced risk, and optimal outcomes for every project

Quality Assurance

Every phase includes quality checkpoints and validation to ensure excellence

Risk Mitigation

Proactive planning and monitoring minimize project risks and delays

Continuous Support

Ongoing support and maintenance ensure long-term project success

Global Footprint & Manufacturing Excellence

With manufacturing facilities and operations spanning across four continents, Mould Craft Tech delivers world-class precast solutions globally. Our strategic locations ensure local expertise with international standards.

Our Global Presence

Manufacturing excellence across continents

India

Manufacturing hub and headquarters

UAE

Middle East operations center

Saudi Arabia

Regional manufacturing facility

United States

North American operations

Regional Expertise

Global Standards

Ready to Get Started?

Partner with Mould Craft Tech for your next industrial project and experience precision, reliability, and unmatched efficiency. Our team is ready to help you transform your vision into reality with our comprehensive industrial solutions.

Initial Consultation

Schedule a no-obligation meeting to review goals, timelines, and technical requirements.

Proposal Development

We create a detailed, tailored proposal outlining the strategy, timelines, cost, and deliverables.

Project Kickoff

We initiate the execution phase with a kickoff meeting, team intro, and communication protocols.

Ready to Start Your Industrial Project?

Get expert consultation and detailed quote within 24 hours

Let's Build Your Future Together

Ready to transform your industrial vision into reality? Our expert team is here to guide you through every step of your project journey.

Phone

+91-9663813849

info@mldcrftech.com

Location

D.No. 15/256, Kallamadai, Velappanayakkanvalasu, Kangayam Taluk, Vellakoil, Tiruppur, Tamil Nadu, 638111

Business Hours

Mon–Fri: 8AM–6PM, Sat: 9AM–4PM, Sun: Closed

Our Location

Send us a Message

Fill out the form below and we'll get back to you within 24 hours.